Addressing Waste Reduction in Automotive Manufacturing Processes: 99exch.com login, Laser247. Com, Yolo247 login

99exch.com login, laser247. com, yolo247 login: Addressing Waste Reduction in Automotive Manufacturing Processes

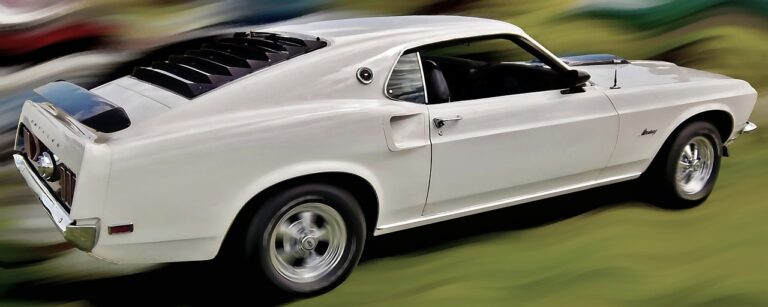

In today’s fast-paced world, sustainability and environmental responsibility have become critical considerations for businesses across multiple industries, including automotive manufacturing. As the demand for vehicles continues to rise, the automotive sector must prioritize waste reduction in its manufacturing processes to minimize its environmental impact. In this blog post, we will explore the importance of waste reduction in automotive manufacturing and provide practical strategies for addressing this pressing issue.

Why is Waste Reduction Important in Automotive Manufacturing?

Waste reduction is essential in automotive manufacturing for several reasons. Firstly, reducing waste helps minimize the environmental impact of the manufacturing processes, such as reducing carbon emissions and conserving natural resources. Additionally, waste reduction can lead to cost savings for automotive manufacturers by optimizing resources and improving efficiency. By implementing waste reduction strategies, automotive companies can enhance their sustainability efforts, meet regulatory requirements, and create a positive brand image among consumers who prioritize eco-friendly practices.

Practical Strategies for Waste Reduction in Automotive Manufacturing

1. Lean Manufacturing: Implementing lean manufacturing principles can help automotive companies identify and eliminate waste in their production processes. This approach focuses on maximizing efficiency, reducing inventory levels, and streamlining operations to minimize waste.

2. Recycling and Reuse: Automotive manufacturers can reduce waste by implementing recycling and reuse programs for materials such as metal, plastics, and other components. By incorporating recycled materials into their manufacturing processes, companies can reduce their environmental footprint and promote circular economy practices.

3. Energy Efficiency: Improving energy efficiency in automotive manufacturing facilities can help reduce waste and lower operational costs. By investing in energy-efficient equipment, implementing energy-saving practices, and monitoring energy consumption, companies can reduce their environmental impact and improve sustainability.

4. Supplier Collaboration: Collaborating with suppliers to optimize packaging, reduce transportation waste, and implement sustainable practices can help automotive manufacturers reduce waste throughout the supply chain. By working together with suppliers, companies can create a more sustainable and efficient production process.

5. Continuous Improvement: Implementing a culture of continuous improvement within automotive manufacturing facilities can help identify opportunities for waste reduction and efficiency enhancement. By encouraging employees to identify and address waste in their daily operations, companies can create a more sustainable and environmentally friendly manufacturing environment.

6. Waste Audits: Conducting regular waste audits to track and analyze waste generation, disposal, and recycling practices can help automotive manufacturers identify areas for improvement and implement targeted waste reduction strategies. By monitoring waste trends and implementing corrective actions, companies can reduce waste and improve sustainability over time.

By implementing these strategies and prioritizing waste reduction in automotive manufacturing processes, companies can enhance their environmental performance, reduce costs, and create a more sustainable business model. Embracing sustainability in automotive manufacturing is not only a responsible choice but also a strategic one that can drive long-term success in an increasingly environmentally conscious market.

FAQs:

Q: How can automotive manufacturers measure their waste reduction efforts?

A: Automotive manufacturers can measure their waste reduction efforts by tracking key performance indicators such as waste generation rates, recycling rates, energy consumption, and cost savings associated with waste reduction initiatives. By monitoring these metrics regularly, companies can assess their progress, identify areas for improvement, and set targets for further waste reduction.

Q: What are the benefits of waste reduction in automotive manufacturing?

A: Waste reduction in automotive manufacturing can lead to several benefits, including cost savings, improved operational efficiency, reduced environmental impact, enhanced sustainability, regulatory compliance, and a positive brand image. By prioritizing waste reduction, automotive companies can create a more sustainable and profitable business model that aligns with consumer preferences for eco-friendly products and practices.